Medres Group has developed inhouse component manufacturing capability with advanced technology to serve both in-house and external needs in the medical device industry. We offer precision turning, laser marking, laser cutting, laser welding, CNC machining, silicon molding, optical measuring, and EDM cutting.

Our advanced metrology lab, climate-controlled warehouse, and expert team ensure a high level of precision in crafting medical components and medical device parts. We respond to requests for short prototyping runs as well as high volume production.

Five pillars of our

component manufacturing

Advanced Equipment

Our investment in state-of-the-art machinery ensures precision and scalability in medical equipment manufacturing, allowing us to handle projects of varying complexities.

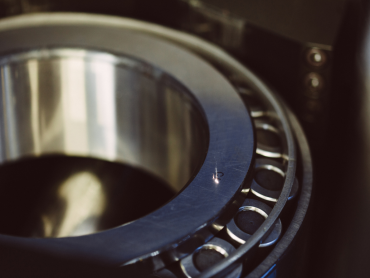

Material Expertise

We have a deep understanding of biocompatible materials and their processing requirements, ensuring durability and compliance in our medical device components.

Quality Control

Each component undergoes rigorous testing in our metrology laboratory, guaranteeing it meets the highest medical industry standards.

Customization

Our team delivers custom medical solutions, tailoring components to client needs and supporting small production runs in design and development.

Training & Skill Development

Continuous training programs keep our team at the forefront of medical technology and industry best practices.

All projects welcome – from the smallest to the largest

At Medres Group, we emphasize our commitment to flexibility in medical manufacturing. Every project, regardless of its scale, receives our dedicated attention. Whether our clients are embarking on the initial stages of medical device design, require pilot production for testing, or are transitioning to mass manufacturing, we cater to their specific requirements.

Our continued investments in advanced component manufacturing technologies underscore our commitment to providing versatile and innovative medical manufacturing solutions.

Quality in

component manufacturing

We run our component manufacturing service according to ISO 9001 standards to ensure speed, efficiency, and regulatory compliance. We can adapt our documentation process to meet the specific needs of our medical device clients.

Our Core Competencies

Precision Turning

Employing lathes for high-precision medical parts, ideal for cylindrical components.

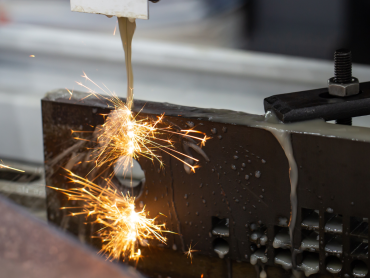

EDM Cutting

Sculpting intricate shapes essential for precision in medical devices.

CNC Machining

Complex shaping for high-quality medical components.

Custom Tool Development

Designing and producing custom tools for increased accuracy in medical device fabrication.

Silicone Molding

Providing versatile components like seals and gaskets for medical devices.

Laser Cutting

Achieving precise cuts for intricate medical device components.

Laser Welding

Advanced laser technology for strong connections in medical device assembly.

Laser Marking

Essential for clear labeling of medical components, ensuring traceability and regulatory compliance.

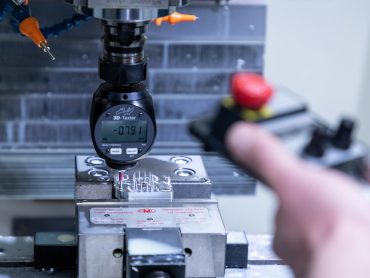

Metrology

Ensuring specification conformity in medical component production.

Ask for a quote –

it’s simple and fast

Complete the inquiry form below with the specifications and we’ll get back to you within 2 days. In case of special needs, please contact us at info@medres.hu.

Thank you for your interest. We look forward to hearing from you!

By submitting this form, I acknowledge that I have read and understood the Privacy Policy and agree to the processing of my personal data for the purposes stated therein.